A brave man who actually built a 'fully automatic egg cracking machine' has appeared, but what exactly is difficult about it?

While the action of 'cracking an egg' is an everyday one, the process of 'holding an egg with moderate force, cracking it so that it doesn't break, and breaking it in two to get the contents out' is quite complicated.

Why is this task so difficult for machines? - YouTube

Over-Engineering An Egg Cracking Machine | Hackaday

https://hackaday.com/2025/09/03/over-engineering-an-egg-cracking-machine/

Shane Wighton, owner of Stuff Made Here, said he's been eating eggs for breakfast for 10 years and has always found it frustrating: He can't crack an egg properly, and the whites get sticky on his fingers.

So Wighton decided to build his own fully automatic egg cracking machine, thinking, 'It wouldn't be that difficult.'

Since fully automatic egg crackers are intended for use in the kitchen, they must be compact and handheld, and be a purely mechanical device with no electronics, software, or lasers.

If an egg shell has a small crack, it becomes difficult to crack cleanly, and it becomes easier for shell fragments to get mixed in when you remove the contents.

So, inspired by the fact that glass with a crack on the surface breaks cleanly along the crack, Wighton came up with a method of 'making a thin crack in an eggshell and breaking it along that crack.'

I was able to successfully crack the egg by holding both sides and pulling to tear the inner membrane.

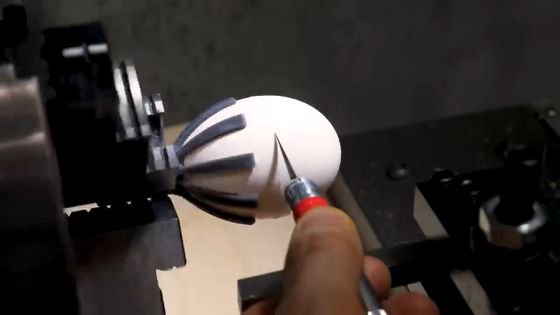

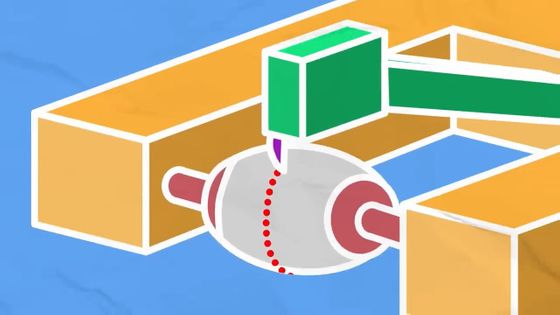

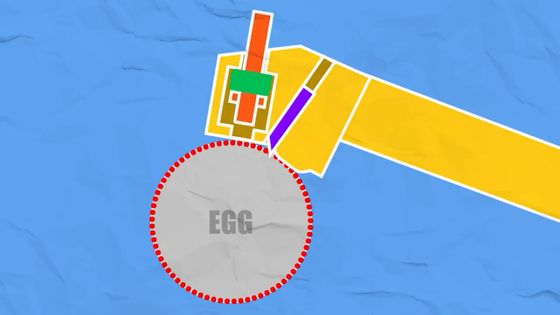

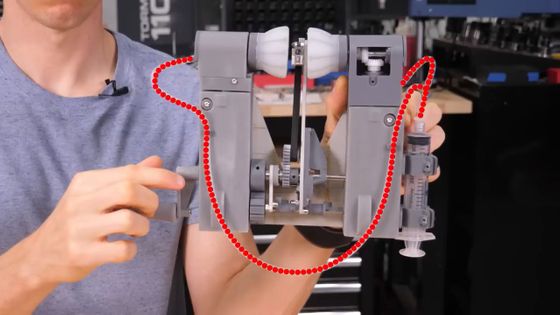

Wighton's method involves first holding the egg in place with grippers on both sides and then using a knife to make a crack all the way around the shell.

The shell is then split open by hitting it with a hammer, and the gripper is rotated downwards and pulled from both sides to release the contents.

Once the contents are removed, the shell is also ejected from the gripper. Furthermore, they want to be able to complete these operations simply by turning the handle.

The first challenge was how to use the gripper to hold eggs, which come in various shapes and are smooth and slippery.

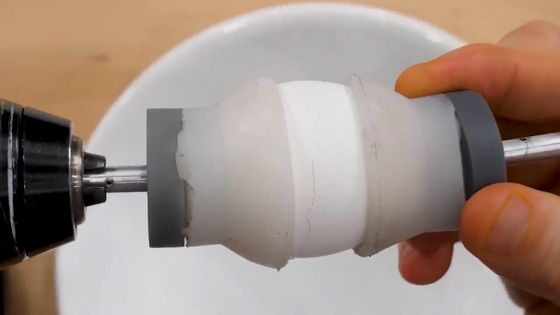

After considering various methods, they decided to use a stretchy silicone mold to hold the egg in place.

The stretchy silicone conforms to the shape of the egg, so it can hold almost any size egg.

In addition, after the egg has cracked, it is ejected using a spring-loaded ejection device installed inside.

However, when they actually tried it, they found that the inner membrane of the egg was surprisingly strong, and that it would not break even when pulled from both sides using only the elastic silicone. The problem was that the elasticity of the silicone limited the amount of torque that could be applied to the egg.

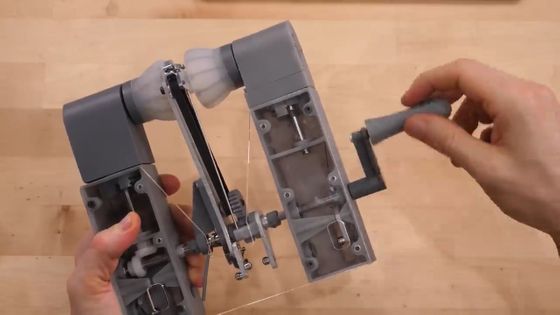

So Wighton came up with a structure that embeds grippers inside the silicone, allowing it to conform to the shape of the egg while applying just the right amount of torque.

This allowed me to crack the egg cleanly.

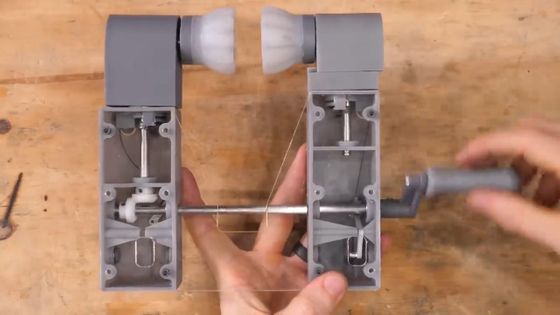

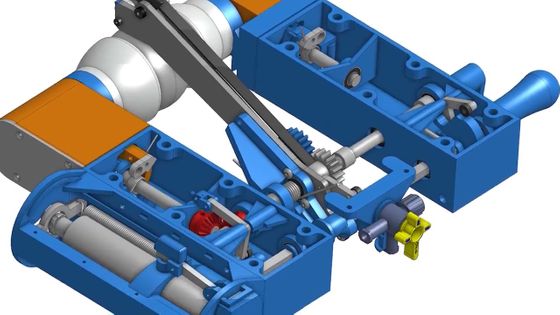

Wighton then used a 3D printer to create many of the parts and create the mechanism that powers the egg gripper.

It also has a spring-loaded mechanism that ejects the eggshells when the gripper has fully rotated.

Next, we will make a knife to crack the surface of the egg and a hammer to hit the shell.

The knife is quite small and can create a crack without breaking it all the way through to the inside.

The hammer is a small, spring-loaded metal rod that taps just above the crack.

Combined, these provide all the hardware needed for a fully automatic egg cracking machine.

However, this hardware does not actually work because there is no 'program' for it to work properly.

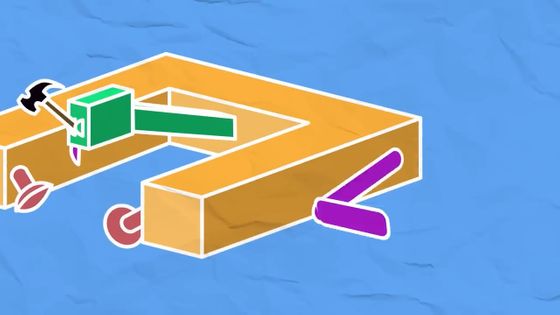

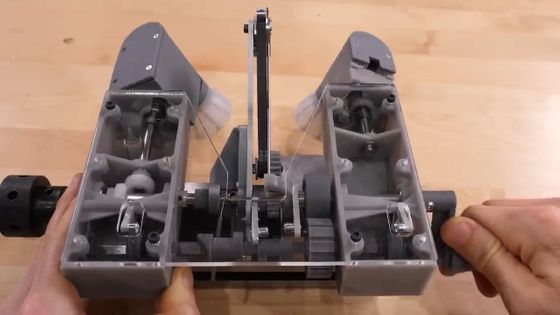

So Wighton designed a mechanism that runs entirely on mechanical algorithms, without the use of a computer.

Even to achieve what may seem like simple actions on paper - 'press a knife against the egg to crack it,' 'release the pressure and hit it with a hammer to break it,' 'pull the shell with a gripper to eject the contents of the egg,' and 'rotate the gripper further to discard the shell with a spring-loaded ejection device' - required an extremely complex device.

'It's incredibly complex and incredibly simple at the same time. You turn the handle and it cracks an egg. That's why it's beautiful,' Wighton said.

I'll set the eggs and try it out.

But it doesn't work. When individual components check each other well but fail when combined, Wighton calls this 'Integration Hell.'

Analysis of the failure identified a problem with the algorithm's programming gears, which were jamming under high loads, which could be fixed by tweaking the design.

We have also improved the mechanism that cracks the eggs.

Strengthening the egg gripper also caused problems with the shell ejection device.

So Wighton came up with a mechanism that 'eliminates the airtightness by letting air between the gripper and the shell, allowing the shell to come off.'

We will test the improved fully automatic egg cracking machine.

Mr. Wighton turns the handle.

The eggs cracked nicely.

Mr. Wighton also has this smile.

Wighton responded to the test results by redesigning 90% of the components to refine the mechanism and embed the shell ejector internally.

This is the completed fully automatic egg cracking machine.

Set the eggs.

When you turn the handle, the parts move in unison.

But for some reason I failed to break it.

The problem this time was with the egg gripper, and the mechanism that uses air to eject the egg shells had a problem where the air pressure was released on one side, causing the shells to fall, but the other shells would not fall.

Wighton fixed the problem with the egg gripper and addressed the shell ejector by installing a valve.

Place the eggs in the fully automatic egg cracking machine again.

Turn the handle.

Cracks will appear on the surface of the egg.

I managed to crack the egg successfully.

The eggshell ejection mechanism also worked well.

Wighton looks pleased.

Finally, Wighton's wife was asked to try out the fully automatic egg cracking machine.

Wighton lets his wife experience the power of an automatic egg cracking machine.

However, my wife's expression was not very good.

When Wighton asked how he rated it out of 10, he gave it a very low rating of '3.'

When Wighton asked for an explanation, his wife simply said, 'It's too big, too complicated and looks ugly.'

Still, Wighton seemed reluctant to give up, saying, 'No, I think it's great, it's beautiful, it's cool.'