Scientists discover the secret to thick, stable beer foam

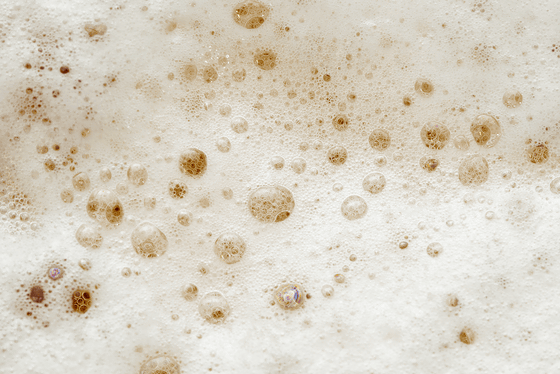

When you pour sparkling beer into a mug or glass, a high layer of white foam forms. With cola or cider, the foam disappears quickly, but with beer, the foam lingers for a long time, almost like a lid. A research team from the Swiss Federal Institute of Technology in Zurich spent seven years researching why beer foam lasts so long, and their paper was published in the academic journal Physics of Fluids.

The hidden subtlety of beer foam stability: A blueprint for advanced foam formulations | Physics of Fluids | AIP Publishing

https://pubs.aip.org/aip/pof/article/37/8/082139/3360405/The-hidden-subtlety-of-beer-foam-stability-A

Scientists unlock secret to thick, stable beer foams - Ars Technica

https://arstechnica.com/science/2025/08/physics-of-why-belgian-beer-foam-is-so-stable/

Foam is essentially gas dispersed in a liquid, and in the case of beer, surfactants such as proteins strengthen the thin film of the bubbles, preventing them from quickly disappearing. However, as gravity causes the liquid inside the film to flow downward, the film becomes thinner, and eventually the small bubbles are absorbed by the larger bubbles and disappear.

The research team, led by Emmanouil Chatzigiannakis of ETH Zurich, conducted experiments using six commercially available beers, including Belgian and Swiss lagers . The researchers focused on foam because they were intrigued by Belgian brewers who said they use foam to control fermentation.

The researchers measured the half-life of beer by pumping air into a glass cylinder to create foam, then recorded and analyzed the time it took for the foam to reduce by half. The results showed that Westmalle Tripel, a triple -fermented beer , had the longest-lasting foam, followed by Feldschlösschen, a lager beer.

On the other hand, the lager beer Chopfab and the Trappist beer Westmalle Extra, which are both fermented once, showed the fastest foam loss. Overall, the researchers found that beers with more fermentations tended to have better foam stability.

Next, to evaluate the physical properties of the liquid and the interface , they used a microfluidic device to artificially create an extremely thin liquid film of beer, and directly observed the thinning process of the film under pressure and the time it took to burst using a microscope. They also measured the viscosity, elasticity, surface tension, and size of particles such as proteins present in the beer.

The results showed that the behavior of the thin beer film differed significantly depending on the type of beer. For example, with lager beer, the liquid film was relatively uniformly thin, and the protein aggregates on the surface did not move. This suggests that the surface had high viscoelasticity and the interface was immobile. On the other hand, with Tripel beer, the protein aggregates in the liquid film actively moved, and Marangoni convection , in which the liquid recirculated, was observed.

Regarding surface tension, Tripel beer showed a larger change in surface tension with respect to changes in concentration than other beers, making it more susceptible to Marangoni convection.

Next, the researchers used liquid chromatography-mass spectrometry to analyze the types and amounts of proteins contained in the three Belgian beers, revealing the amounts of lipid transfer protein 1 (LTP1) and Serpin Z4, which contribute to foam stability. The amount of LTP1 increased with increasing number of fermentations, from single to double to triple fermentations. Furthermore, Serpin Z4 was found to be most abundant in double-fermented beers.

In single-fermentation beers, LTP1 exists as small spherical particles on the surface of the foam, creating viscosity and contributing to foam stability. After two fermentations, LTP1 is partially denatured, forming a more mesh-like structure that further enhances foam stability. During triple fermentation, the protein is further degraded, resulting in fragments with both hydrophobic and hydrophilic ends that are incompatible with water. As a result, in triple-fermentation beers, LTP1 behaves like a surfactant, reducing surface tension and making the foam extremely stable.

'Foam stability is not as simple as adjusting a single factor,' said Jan Vermant, one of the researchers. 'The key is to focus on one mechanism at a time, and beer naturally does this well. We've pinpointed exactly what that mechanism is.'

Related Posts:

in Science, Posted by log1i_yk