Google once tried to make an 'American-made smartphone' as President Trump wanted, but it ended in disappointment.

US President Donald Trump is eager for 'Made in America' smartphones, and

Trump's pressure on Apple to make All-American phones ignores the last tech giant that tried and failed | Fortune

https://fortune.com/2025/07/05/what-apple-trump-can-learn-google-motorola-moto-x-made-in-america-smartphone/

In 2011, Google acquired Motorola 's mobile phone business ( Motorola Mobility ), a major telecommunications equipment manufacturer, for $12.5 billion (approximately 960 billion yen at the time) .

Google acquires Motorola, Android's evolution will accelerate with the acquisition of device manufacturers - GIGAZINE

Having thus entered the mobile phone business, Google took a big gamble in 2013 by manufacturing its Motorola Mobility smartphone, the Moto X , in the US. In a blog post at the time, Motorola Mobility said, 'Conventional wisdom said it couldn't be done. Experts said costs were too high, American manufacturing capacity was waning, and the US workforce was too inflexible.'

However, despite Motorola Mobility, a long-established smartphone manufacturer, teaming up with the mega-Big Tech giant Google, this American smartphone project fell apart after just one year. Fortune interviewed several people involved, as the Moto X case offers new insights as President Trump continues to strongly advocate for smartphone manufacturing in the United States.

Outlook for Moto X

To differentiate the Moto X from other models, Moto offered customers who bought it directly from its website the option to customize it with dozens of colors and materials (including bamboo and walnut back covers), as well as personalized engraving. Moto hoped that this high level of customizability would give it an advantage over Apple and Samsung, which only sell standardized lineups.

Motorola Mobility also promoted its 'Made in America' marketing, emphasizing that it would be a patriotic alternative to foreign-made competing products. The opening ceremony for the factory built in Fort Worth, Texas, was a grand affair attended by the governor of Texas at the time and Mark Cuban, a popular TV investor.

The Moto X parts themselves were imported from Asian subcontractors, and the only work carried out in the US factory was assembly. Even though it was just assembly, labor costs were high, and according to company executives at the time, the hourly wage of workers was about three times higher than in China, but the Moto X was sold at a price that was profitable enough. In addition, the factory secured a baseline of production and demand by selling standard versions of the Moto X to carriers.

By

◆Moto X's US factory

In a 2017 interview , Apple CEO Tim Cook pointed out that the concentration of manufacturing in Asia rather than the United States is not due to wage differences, but that China is no longer a 'low-cost labor source.' Rather, China's strength is its overwhelming number of blueprints for parts, mold engineers, and skilled workers, Cook said, 'In the United States, I don't know if you could fill a room with mold engineers. In China, you could fill the size of several football fields.'

The contract manufacturer that ran the Moto X factory , Flextronics, was aware of this problem and had to recruit engineers from around the world, including Hungary, Israel, Malaysia, Brazil, and China. Fort Worth, on the other hand, was a center for telecommunications equipment manufacturing, so assembly line workers and supervisors could be hired locally.

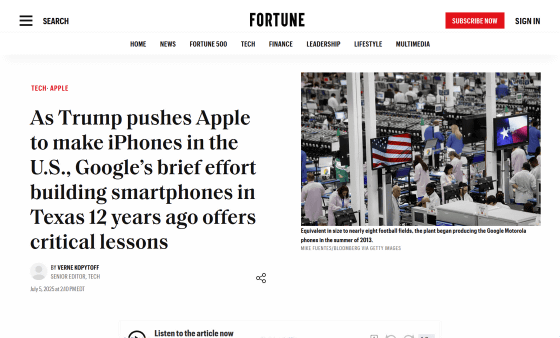

Motorola Mobility's Fort Worth plant, which has an area the size of about eight football fields and employs about 3,800 people, began production in the summer of 2013. Mark Randall, who led Motorola Mobility's supply chain and operations at the time, said that Texas was a manufacturing-friendly state and that the Fort Worth plant was able to receive preferential treatment, such as tax breaks for employee training.

◆ Challenges faced by the Moto X

The Moto X, Motorola Mobility's first smartphone under Google's umbrella, was sold for $579 (about 57,000 yen at the time) for an unlocked entry-level model. The Moto X featured a rounded back and advanced voice recognition capabilities for the time, allowing users to set reminders and search for driving directions by saying 'Okay, Google now.'

However, critics gave the Moto X mixed reviews, praising the device's customizability and overall design, but criticizing the base model's disappointing 16GB storage capacity and the inferior display quality compared to competing smartphones.

Initially, the Fort Worth factory produced 100,000 smartphones per week, but production dropped significantly over time. About 900,000 Moto Xs were sold worldwide in the first quarter of 2014, far short of the 26 million iPhone 5s sold by Apple during the same period. Five months after the launch of the Moto X, its price had fallen to $399 (about 39,000 yen at the time), and nine months later the number of employees at the factory had fallen to about 700, less than one-fifth of its peak.

While some blamed the Moto X's poor sales on a small advertising budget, one of the company's biggest miscalculations was that most consumers didn't care where their smartphones were made. Mark Rose, who was senior director of product management at Motorola Mobility at the time, said, 'One of the things we learned was that products assembled in America just didn't resonate.'

In addition, by allowing customers to customize the color and material when ordering online, there were disadvantages such as not being able to produce and stock in advance, and the rate of returns increased due to customers being disappointed with the color. Another issue was that Motorola Mobility had a weak market share compared to competitors such as Apple and Samsung, and was unable to negotiate prices favorably with suppliers.

In the end, Google decided to close the Fort Worth factory and sold Motorola Mobility's smartphone business to Lenovo in 2014. Since most of the patent portfolio remained in Google's hands, some believe that one of the reasons for acquiring Motorola Mobility, 'to obtain patents and reduce the risk of future litigation,' has been achieved.

Google sells Motorola Mobility smartphone business to Lenovo - GIGAZINE

Lessons learned from the Moto X case

Fortune points out that the reason Google and Motorola Mobility's plans to make smartphones in the US failed was, 'In the end, it seems like it had little to do with where the Moto X was assembled. It just didn't sell enough to justify putting an assembly line in the US.' Randall is blunt: the Moto X's failure had nothing to do with American manufacturing, but because the iPhone was better and had better brand recognition.

Since Apple has an overwhelmingly larger sales and market share than Motorola Mobility at the time, even if it were to build a smartphone factory in the U.S., it would not necessarily face the same challenges. In addition, it has been about 10 years since Moto X production in the U.S. ended, and factories have become more automated, so it may be easier to reduce costs in U.S. smartphone factories than before.

On the other hand, the difference remains that while in the United States it is not possible to suddenly add thousands of employees to handle unexpected sales, China can. 'China's ability to flex its workforce when a project is going really well is incredible. It's also incredible their ability to shrink the workforce,' Randall said.

'What's clear is that Motorola Mobility's 'Made in America' experiment lasted just over a year, and for more than a decade, no other major smartphone maker dared to try something similar again,' Fortune said.

Related Posts:

in Note, Posted by log1h_ik