Using 'moon sand' to create solar cell modules could cut launch costs by 99%

The fine sand that has accumulated on the surface of the moon is called

Moon photovoltaics utilizing lunar regolith and halide perovskites: Device

https://www.cell.com/device/fulltext/S2666-9986(25)00060-2

Solar cells made of moon dust could power future space exploration | EurekAlert!

https://www.eurekalert.org/news-releases/1078443

Moon dust may help astronauts power sustainable lunar cities. Here's how. | Space

https://www.space.com/the-universe/moon/moon-dust-may-help-astronauts-power-sustainable-lunar-cities-heres-how

When conducting long-term exploration on the Moon or building a lunar base, it is inevitable to address the issue of supplying energy for the various equipment and activities required. Until now, most of the energy on the Moon's surface has been generated by solar cells transported from Earth, but it is too costly to transport enough solar cells to sustain large-scale exploration or settlement activities.

'The solar cells currently in use in space are amazing, with efficiencies of 30-40 percent, but that efficiency comes at a price,' said Felix Lang, a space solar power researcher at the University of Potsdam. 'They're very expensive and relatively heavy, using glass or thick foil as a cover. It's difficult to justify shipping all those solar cells into space.'

Instead of transporting solar cells from Earth, Lang and his team came up with a method to manufacture solar cell modules on-site using lunar regolith. Specifically, the solar cell module is made of perovskite solar cells , which use a crystalline structure called perovskite , and glass to protect it. The glass is replaced with 'moon glass' made from lunar regolith.

Perovskite solar cells themselves are lightweight and flexible, and can convert sunlight into electricity with high efficiency, but they do not provide any protection from the strong radiation and micrometeorites on the lunar surface. Therefore, to operate perovskite solar cells on the lunar surface, the surface needs to be protected with glass or other materials.

To demonstrate the idea of 'making solar cell glass from lunar regolith,' the research team conducted experiments using a material that mimicked regolith. There is no need for a complicated refining process to make moon glass from regolith; simply concentrating sunlight and heating it to high temperatures can melt the regolith and turn it into glass. The research team reports that they have successfully manufactured perovskite solar cell modules using the moon glass made in this way.

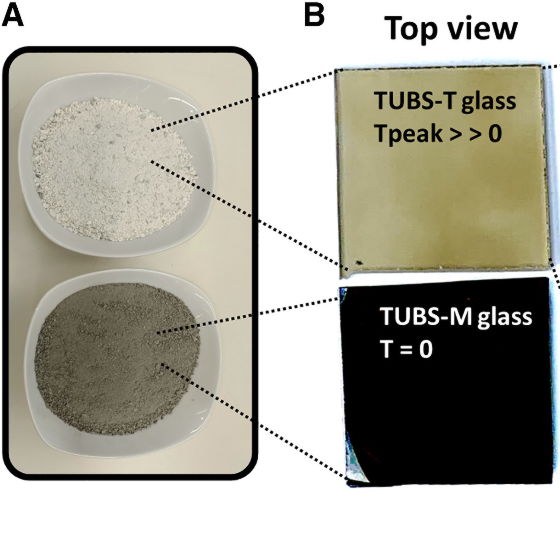

Below, A is 'TUBS-T (top),' which reproduces the regolith with a low content of heavy metal oxides found in the highlands of the moon, and 'TUBS-M (bottom),' which reproduces the regolith with a high content of heavy metal oxides found in the lowlands of the moon, and B is moon glass made from these materials. In this study, moon glass made from 'TUBS-T,' which is lighter in color and more transparent to light, was used to manufacture solar cell modules.

Ordinary glass made on Earth would turn brown when placed on the lunar surface due to strong cosmic rays, gradually reducing its sunlight transmittance and the efficiency of its solar cells. On the other hand, moon glass is brown from the start due to impurities in the regolith, so it is less likely to turn brown and is more resistant to cosmic rays.

Perovskite solar cell modules made from moon glass have been able to achieve a conversion efficiency of 10% by fine-tuning the thickness of the glass and the composition of the solar cells. Although this is significantly less efficient than solar cells made on Earth, producing moon glass on the moon's surface reduces the launch weight required to manufacture the solar cells by 99.4% and reduces transportation costs by 99%. As a result, the research team claims that the amount of electricity generated per gram of weight launched from Earth into space can be up to 100 times higher.

'If we're going to reduce the weight by 99 percent, we don't need super-efficient solar cells with 30 percent efficiency. We can just make a lot of them on the moon,' Lang said. 'Plus, other solar cells degrade over time, but ours are more stable against radiation.'

Although the results of this research are promising, there are still many uncertainties, such as 'It is unclear whether moon glass can be made from regolith in a similar low gravity environment different from Earth,' 'The solvents used to process perovskite may deteriorate when exposed to a vacuum,' and 'The extreme temperature differences between day and night on the moon may cause the material to repeatedly contract and expand, which may affect the stability of the solar cells.' Therefore, the research team wants to actually test the production of solar cells on the moon.

'From extracting water for fuel to building homes with lunar bricks, scientists have found ways to use lunar sand. Now we can also turn it into solar cells, which could provide the energy needed for future lunar cities,' Lang said.

in Science, Posted by log1h_ik