It turns out that simply gluing a '3D-printed board' to an old military aircraft can save 2.2 billion yen in fuel costs per year

The U.S. Air Force has announced that by adding small deflectors printed with a 3D printer to the fuselage of

Cutting-Edge Microvane Technology Ready to Modernize C-17 Fleet > Eglin Air Force Base > Article Display

https://www.eglin.af.mil/News/Article-Display/Article/4029642/cutting-edge-microvane-technology-ready-to-modernize-c-17-fleet/

Little vanes glued to planes promise big savings for US Air Force

https://newatlas.com/military/ticky-little-vanes-bring-big-savings-us-air-force/

C-17 Globemaster: Cutting-Edge, Drag-Reducing 'Microvane Tech' Set To Modernize USAF's Aircraft Fleet

https://www.eurasiantimes.com/usaf-enters-final-evaluation-phase-for-microvane/

The C-17, a large cargo plane manufactured by McDonnell Douglas (now Boeing), was introduced in 1995 as the successor to the Lockheed C-141 Starlifter, which was the main aircraft of the company. Since then, it has been used for logistics for the United States Air Force, Royal Air Force, Canadian Air Force, Australian Air Force, and other organizations for nearly 30 years.

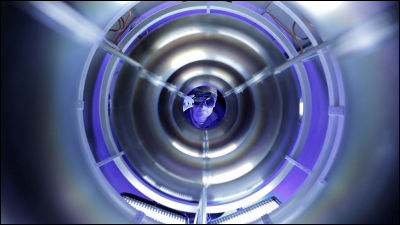

The C-17 has a problem with turbulence, which can lead to poor fuel economy, because the rear of the fuselage where the cargo door is located is angled upward. This is also the reason why the vertical tail and horizontal stabilizer are located high up and away from the fuselage.

by

The U.S. Air Force, which was working on the fuel efficiency issue, made a modification by creating 12 'micro-deflectors' (microvanes), which are thin blades measuring 4 x 16 inches (about 10 x 41 cm), using a 3D printer and attaching them to the rear of the fuselage with a strong adhesive.

As a result of this 'modernization,' the drag and fuel consumption of the aircraft was reduced by 1%. While 1% may not seem like a big deal, the Department of Defense estimates that the improved fuel efficiency of the large cargo planes that are so important to the U.S. military could save $14 million a year.

In particular, in the

Currently, six C-17s are undergoing modifications in preparation for the Logistics Services Assessment (LSA), the final evaluation stage before full deployment, and ultimately all operational aircraft are expected to be fitted with the microvanes.

by 143d ESC

The US Air Force has called the Microvane a 'low-cost, innovative force multiplier,' as the small cost of installing the Microvane improves operational capabilities and saves costs. Allies, including Canada and the UK, have also shown strong interest in the Microvane.

'The more fuel we save, the more responsive and operationally efficient our Air Force will be,' said Roberto Guerrero, deputy assistant secretary of the Air Force for operations, energy, safety and occupational health. 'By adding modern technologies like Microvane to older aircraft, we are saving significant fuel costs and building a capability that is essential to staying competitive in this era of Great Power Competition.'

Related Posts:

in Vehicle, Posted by log1l_ks