I built my own smartwatch from scratch for my son who has type 1 diabetes

Andrew Childs, a New York-based software developer, has written a blog post about how he built a custom smartwatch for his 9-year-old son, who has type 1 diabetes.

Building a (T1D) smartwatch from scratch

For type 1 diabetes, blood sugar levels must be constantly monitored and insulin must be administered regularly using an insulin pump or injections. Mr. Childs decided to develop his own smartwatch with the aim of enabling his son, who has type 1 diabetes, to manage his blood sugar levels at school or during exercise without having to carry a smartphone.

Childs started out by using the M5Stick as his first prototype to display blood glucose data, but the model had poor battery life and wasn't waterproof enough.

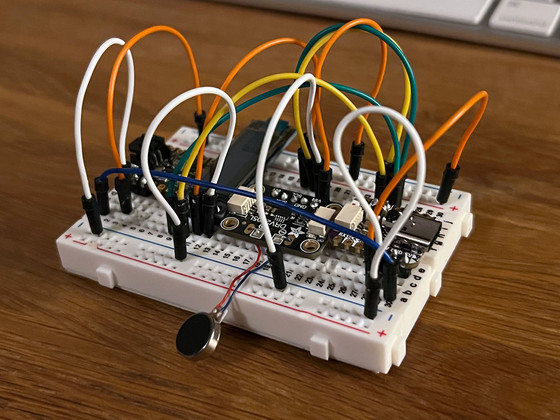

Childs then connected modules from

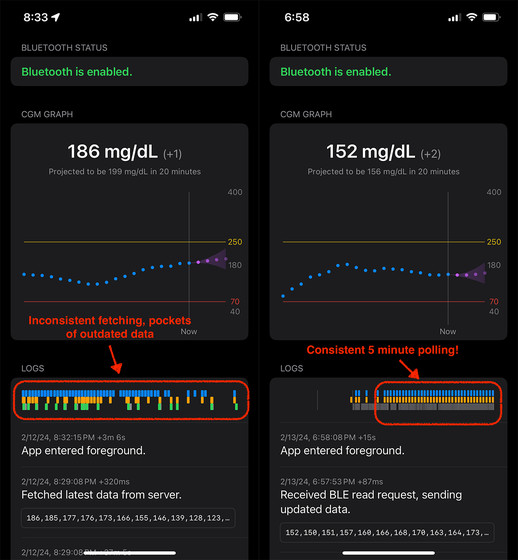

According to Childs, one of the biggest technical challenges was 'establishing a reliable Bluetooth Low Energy (BLE) connection.' At first, there were problems connecting to the iOS app, but they eventually solved it by initiating a connection from the smartwatch every five minutes.

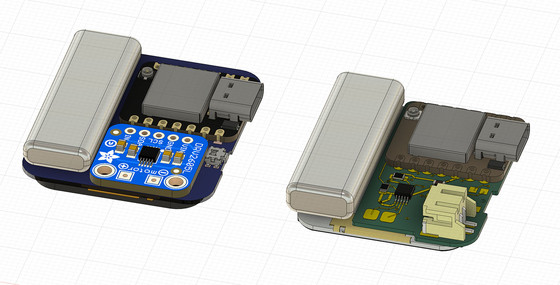

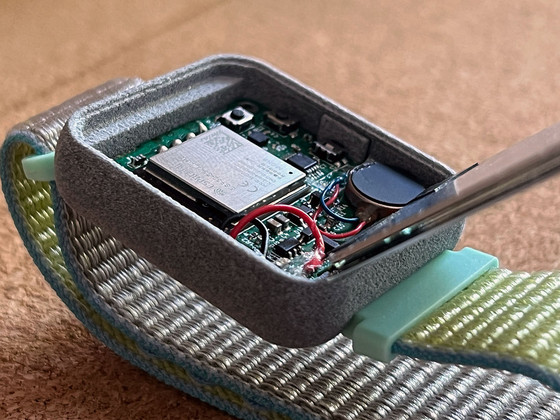

After that, he moved on to developing custom PCB boards to miniaturize the device, and Childs created a total of nine versions of the board. He used a four-layer board, added an accelerometer for the pedometer, rearranged the components, and devised a way to store the battery, making repeated improvements to the details.

The case was 3D printed using the Multi Jet Fusion (MJF) method in collaboration with 3D printing company Fictiv, and was coated with a matte gray waterproof paint to ensure it was waterproof.

The display is a 1.69-inch, 240 x 280 pixel

Charles and his son have been using the prototype for over six months and have found it useful in real life, detecting fluctuations in blood sugar levels early and allowing them to respond before the alarm goes off.

Childs said that one of the most notable aspects of this smartwatch development project was the use of modern AI tools, especially ChatGPT, which was a great help in the early stages of development. He also said that he gained a deeper understanding of the practical challenges of hardware development in terms of manufacturing and cost, as well as the appropriateness of the pricing of existing commercial smartwatches.

Childs had been considering open sourcing the project, but with Google's announcement of open sourcing Pebble OS and the revival of Pebble at the end of January 2025, he said he needed to reconsider the project's future direction.

in Hardware, Posted by log1i_yk